Mechanical Safety: Preventing Accidental Opening

That loop also ensures that the clasp closure has to overcome spring force to open. It gives the pin a locking margin — the force required to open it is nontrivial, so it doesn’t open accidentally from bumps or motion. That improves safety, especially when used in clothing near skin.

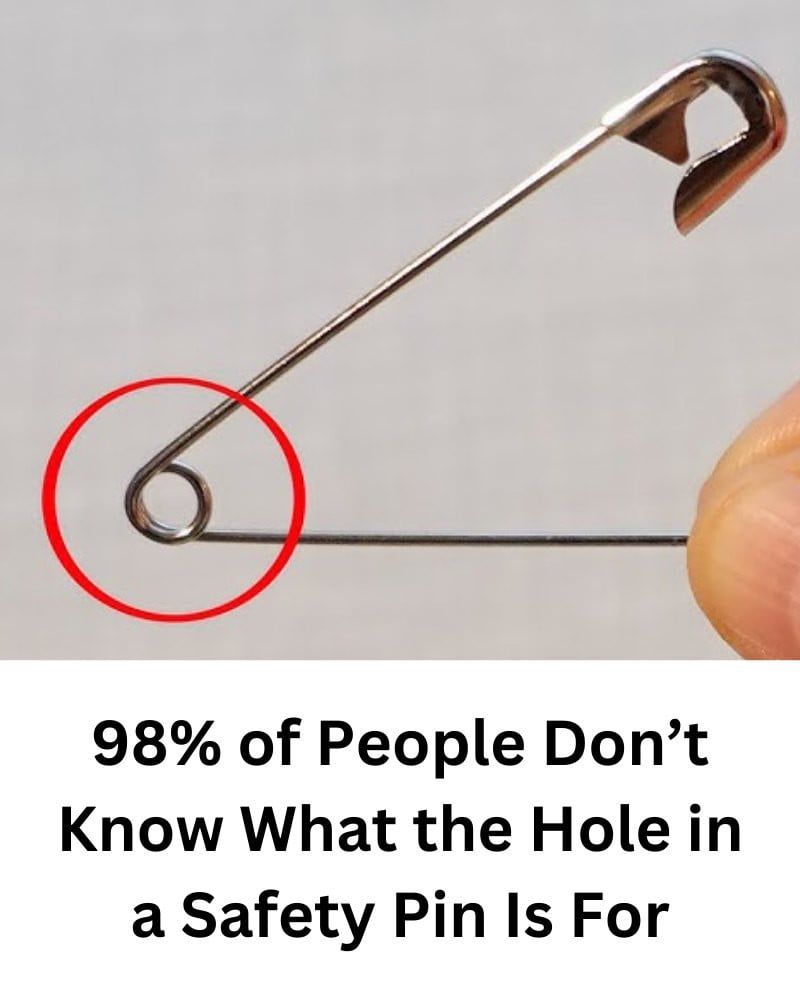

Thus, the small circle is part of a built‑in locking mechanism: it maintains pressure over the catch, keeping it closed until intentionally opened.

Historical Evolution: How the Loop Came to Be

To appreciate the loop more, we must step back into the history of the safety pin. The modern safety pin was patented in the mid-1800s (circa 1849), but its conceptual ancestors go back much further. Over time, the design evolved, and the loop became refined.

Early Fasteners & Predecessors

Before the safety pin, ancient civilizations used fibulae (a kind of brooch) to fasten clothing — classic in Roman, Greek and Celtic traditions. Those brooches often featured spring mechanisms, coils, and loops to allow movement and secure fastening.

In those early devices, you sometimes find curls, coils or loops incorporated into the hinge mechanism — essentially prototypes of the modern loop. These were large, ornate, and bulky, but the principles are analogous.

Invention of the Modern Safety Pin

The modern safety pin as we know it was invented by an American mechanic. The brilliance was designing a clasp that covers the sharp point and a spring hinge built into the same wire. The pivot or coil region had to both allow movement and ensure safety. That hinge was implemented via a loop or twist in the wire.

Over time, improvements refined that loop: making it more compact, more reliable, less prone to failure, and adjustable in size. The proportions of the loop vs. wire gauge vs. material properties matter critically. Engineers studied metal fatigue, elasticity, yield strength, and manufacturing tolerances.

Variations emerged: elongated coils, tighter loops, double coils, even micro‑spiral hinges in custom pins. But the principle remains: that little circle is where the mechanical “spring” lives.

As manufacturing techniques improved (better metal alloys, precise wire forming), the loop could be smaller, stronger, and more durable. That’s why older vintage safety pins often have larger or more visible loops, whereas modern ones make the loop almost invisible — yet still essential.

Variants, Innovations & Design Hybrids